You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Infantry Vehicles

- Thread starter KevinB

- Start date

Colin Parkinson

Army.ca Myth

- Reaction score

- 9,171

- Points

- 1,160

Like this?

- Reaction score

- 7,300

- Points

- 1,160

Just a reminder

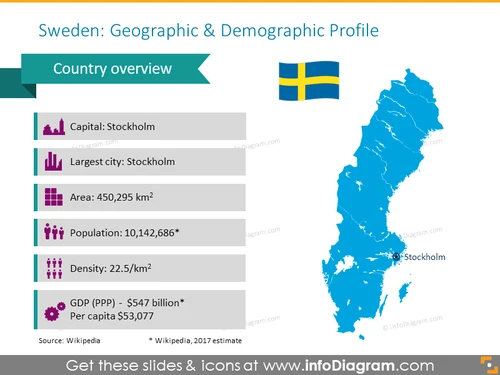

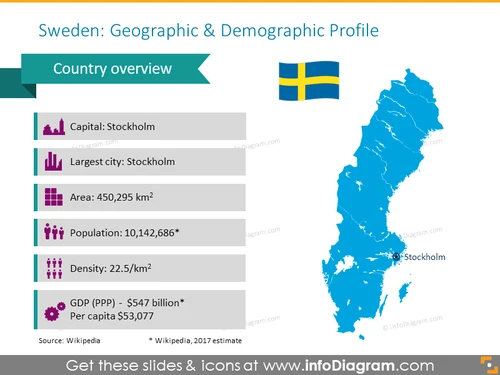

Sweden Population 10.5 Million

Canada Population 38.6 Million

Sweden GDP PPP 547 BUSD

Canada GDP PPP 1990 BUSD

data.worldbank.org

data.worldbank.org

Same latitudes. Similar climates. Similar indigenous populations. Similar resources.

Sweden Population 10.5 Million

Canada Population 38.6 Million

Sweden GDP PPP 547 BUSD

Canada GDP PPP 1990 BUSD

GDP, PPP (current international $) - Canada | Data

GDP, PPP (current international $) - Canada from The World Bank: Data

Same latitudes. Similar climates. Similar indigenous populations. Similar resources.

- Reaction score

- 6,328

- Points

- 1,310

They also had the unfortunate situation of having hostile neighbours and no NATO protection for 80 years. You get pretty good at doing right the first time when you don't have the time, space, or friends to fool around.Same latitudes. Similar climates. Similar indigenous populations. Similar resources.

Canada may as well be on another planet in our mindset.

OldSolduer

Army.ca Relic

- Reaction score

- 12,340

- Points

- 1,140

What planet did they film that on? Tatooine??Meanwhile - from the people that brought you

View attachment 76668View attachment 76669View attachment 76670

and

and

The next generation Infantry Vehicle

Brought to you by The Scandinavian School of Design - Where form follows function

and our sponsor

- Reaction score

- 7,300

- Points

- 1,160

What planet did they film that on? Tatooine??

May have been. But now that extra-terrestrial technology is being applied to commutes in Tuscany.

Home | Jetson - Personal Electric Aerial Vehicle

Your personal aircraft in aluminium and carbon fibre, powered with eight powerful electric motors.

Yours for US$98,000 with 8,000 down and delivery in 2024/25. Bit of a backlog.

Colin Parkinson

Army.ca Myth

- Reaction score

- 9,171

- Points

- 1,160

I can see Civ aviation having a aneurysm when someone who is not a pilot wants to fly one in a urban area.

- Reaction score

- 7,300

- Points

- 1,160

I can see Civ aviation having a aneurysm when someone who is not a pilot wants to fly one in a urban area.

Why? I just dropped myself in the mail and posted myself.

Colin Parkinson

Army.ca Myth

- Reaction score

- 9,171

- Points

- 1,160

We called Transport Canada the "Department of No" Let's just say that innovation was not their strong suit.

- Reaction score

- 7,300

- Points

- 1,160

Think Defence has started a really interesting looking series on British Army Vehicle development from WW2 to the present day. I have started to read but I haven't even managed to read what he has published so far.

www.thinkdefence.co.uk

www.thinkdefence.co.uk

www.thinkdefence.co.uk

www.thinkdefence.co.uk

Needless to say my eye was caught by his use of one of my favourite British Army vehicles - the Saladin - firing the same 76mm ammunition as the later Scorpion and the Cougar as well as some Aussie M113s.

Despite the shockers included here I suggest that standardization is a peacetime luxury that is hard pressed to survive contact. Even as the Ukrainians struggle to keep their originally standardized arsenal equipped they find themselves willing to accept anything that will get the job done. Especially when it is being eliminated faster than they can find replacements. The Brits found themselves in exactly this situation between 1939 and 1945 with the worst period being 1939 to 1942. After 1942 they had access to a steady stream of equipment from American factories. But even that wasn't standardized. Allied requirements, lessons learned and the enemy's constant adaptation and insisting in having a vote all ensured that everything was constantly being "upgraded" and new specifications being written.

We can create an army in peacetime to fight a 90 day war (Three Day wars are better) but can we create an army that can fight with what they can beg, borrow or steal? Where "Airborne Initiative" is the order of the day?

Even the Wehrmacht, originators of "Ordnung muss sein" found themselves using anything they could capture alongside whatever their factories were producing on the day.

Diminishing Returns - The British Army and its Vehicles - Series Introduction - Think Defence

This series of blog posts is I hope a fair-minded and accurate history of the British Army’s armoured and protected mobility vehicles from the Post War period to early 2023.

www.thinkdefence.co.uk

www.thinkdefence.co.uk

Diminishing Returns – The British Army and its Vehicles – The Fifties - Think Defence

The end of WWII was followed by a period of reflection for the British Army, but not a long one.

www.thinkdefence.co.uk

www.thinkdefence.co.uk

Needless to say my eye was caught by his use of one of my favourite British Army vehicles - the Saladin - firing the same 76mm ammunition as the later Scorpion and the Cougar as well as some Aussie M113s.

The Need For Standardisation

Faced with an almost impossible industrial and manufacturing problem, the early days of the war meant the British Army had to make do with what vehicles it could.

The diversity of equipment in combat and support arms placed significant strains on logistics, support and training. The more vehicles, the more spare parts, the more spare parts, the smaller economies of scale.

The lack of commonality across components and standards in such seemingly mundane items as screw threads resulted in large quantities of equipment being abandoned in North Africa between 1941 and 1942.

[American sourcesestimated this lack of standard threads alone added £25m to the cost of war. Over a billion Pounds today when adjusted for inflation]

As the war closed, a period of taking stock was in order.

With wartime pressures to maximise production from different manufacturers gone the demand for standardisation and a reduction of vehicle types was a vital requirement of the Ministry of Supply.

In 1951, Major R Campagnac RASC and Major P E C Hayman of the 15th/19th The Kings Royal Hussars published their review of wartime transport.

The Second World War 1939-1945: Army Fighting, Support and Transport Vehicles and the War Office Organisation for their Provision, The War Office, 1951

The report was published in two parts

It noted that by the end of 1944, there were over 600 makes/variants of support and transport vehicles in service with the British Army and much of it was based on civilian designs that were unsuited to military use.

- Fighting Support and Transport Vehicles and War Office Organisation for Their Provision: Part 1, Common Problems, 1939-1945

- Fighting Support and Transport Vehicles and War Office Organisation for Their Provision: Part 2, Unarmoured Vehicles, 1939-1945

A number of objectives for consideration came from this.

As the War ended and various pieces of the Ministry of Supply were closed and a number of establishments merged, in 1952, the Fighting Vehicle Research and Development Establishment (FVRDE) was created, located on Chobham Lane in Chertsey.

- The Army had to improve the precision and clarity of its requirements

- A research and design establishment must be set up to realise these requirements

- Manufacturing of military equipment must be done with standardisation in mind

- Military transportation equipment should be designed for military requirements

Standardisation meant as few engines, transmissions, wheels and other components as possible. Vehicles of different designs would be designed and built around these common components, engines especially.

Despite the shockers included here I suggest that standardization is a peacetime luxury that is hard pressed to survive contact. Even as the Ukrainians struggle to keep their originally standardized arsenal equipped they find themselves willing to accept anything that will get the job done. Especially when it is being eliminated faster than they can find replacements. The Brits found themselves in exactly this situation between 1939 and 1945 with the worst period being 1939 to 1942. After 1942 they had access to a steady stream of equipment from American factories. But even that wasn't standardized. Allied requirements, lessons learned and the enemy's constant adaptation and insisting in having a vote all ensured that everything was constantly being "upgraded" and new specifications being written.

We can create an army in peacetime to fight a 90 day war (Three Day wars are better) but can we create an army that can fight with what they can beg, borrow or steal? Where "Airborne Initiative" is the order of the day?

Even the Wehrmacht, originators of "Ordnung muss sein" found themselves using anything they could capture alongside whatever their factories were producing on the day.

Colin Parkinson

Army.ca Myth

- Reaction score

- 9,171

- Points

- 1,160

Actually the Brits started the standardizing even before the war. They dropped plans to move away from .303 and met with Canadian truck makers to develop standard design patterns leading to the CMP designs. They also sent the plans for the corvettes and frigates to Canada and the US. Unfortunately those plans were incomplete and it delayed the start of construction in Canadian yards till the plans had been fleshed out more.

lenaitch

Army.ca Veteran

- Reaction score

- 2,915

- Points

- 1,160

Most people can barely operate machinery in two dimensions let alone three.I can see Civ aviation having a aneurysm when someone who is not a pilot wants to fly one in a urban area.

Last edited:

FJAG

Army.ca Legend

- Reaction score

- 11,311

- Points

- 1,160

It was a lot easier then when all one needed was the fundamentals of auto mechanics and most engines looked the same and operated on a few parts, some of which in a pinch, could be swapped around or McGyverized. Todays auto mechanics need a degree in engineering, an electronics workshop and highly specialized parts that come from a just-in-time fabrication shop in Tokyo. (I exaggerate, but just a little) A lot of today's stuff just isn't amenable anymore to rough field mechanics. I think this is why the Ukrainians are able to cope. The gear they are working on is still fundamentally simple. That's going to change once the hodge-podge of Western gear makes its way into the field.Even the Wehrmacht, originators of "Ordnung muss sein" found themselves using anything they could capture alongside whatever their factories were producing on the day.

- Reaction score

- 7,300

- Points

- 1,160

It was a lot easier then when all one needed was the fundamentals of auto mechanics and most engines looked the same and operated on a few parts, some of which in a pinch, could be swapped around or McGyverized. Todays auto mechanics need a degree in engineering, an electronics workshop and highly specialized parts that come from a just-in-time fabrication shop in Tokyo. (I exaggerate, but just a little) A lot of today's stuff just isn't amenable anymore to rough field mechanics. I think this is why the Ukrainians are able to cope. The gear they are working on is still fundamentally simple. That's going to change once the hodge-podge of Western gear makes its way into the field.

I think you might be anticipating too much. Both in WW2 and today but especially today. If it breaks get a new one. If you can't get a new one keep your head down until you can.

Colin Parkinson

Army.ca Myth

- Reaction score

- 9,171

- Points

- 1,160

Most of the modern technicians are not up to the task either and just swap components till they get a fix. Very few understand what is going on in those components.It was a lot easier then when all one needed was the fundamentals of auto mechanics and most engines looked the same and operated on a few parts, some of which in a pinch, could be swapped around or McGyverized. Todays auto mechanics need a degree in engineering, an electronics workshop and highly specialized parts that come from a just-in-time fabrication shop in Tokyo. (I exaggerate, but just a little) A lot of today's stuff just isn't amenable anymore to rough field mechanics. I think this is why the Ukrainians are able to cope. The gear they are working on is still fundamentally simple. That's going to change once the hodge-podge of Western gear makes its way into the field.

OldSolduer

Army.ca Relic

- Reaction score

- 12,340

- Points

- 1,140

And I love to make this argument - keep it simple, stupid. No fancy electronics (they can break at the worst times). I learned to drive a Dodge 3/4 ton just before they were retired. They were shit simple.It was a lot easier then when all one needed was the fundamentals of auto mechanics and most engines looked the same and operated on a few parts, some of which in a pinch, could be swapped around or McGyverized. Todays auto mechanics need a degree in engineering, an electronics workshop and highly specialized parts that come from a just-in-time fabrication shop in Tokyo. (I exaggerate, but just a little) A lot of today's stuff just isn't amenable anymore to rough field mechanics. I think this is why the Ukrainians are able to cope. The gear they are working on is still fundamentally simple. That's going to change once the hodge-podge of Western gear makes its way into the field.

- Reaction score

- 7,300

- Points

- 1,160

And I love to make this argument - keep it simple, stupid. No fancy electronics (they can break at the worst times). I learned to drive a Dodge 3/4 ton just before they were retired. They were shit simple.

You pay extra to take out the electronics.

The most important thing? Cheap and Plenty.

Vehicles would be designated as CombaT (CT) or General Service (GS) (eventually changing to CommerciaL or CL) differentiating those that would be drawn from civilian designs from those that were built to military specifications.

Land Rover

A long story, and is way too much for even a long blog post, but the story of Land Rover is the story of the Austin Champ, or more specifically, the over-ambition of the Austin Champ.

The Champ had an advanced design even having independent torsion bar suspension and incredible fording capability, but it was expensive.

By the mid-fifties, the need for the sophisticated Champ was being questioned, especially when a Land Rover was less than half the price.

The rest is history, from 1958, the Land Rover became the British Army’s standard light general service vehicle and is so to this day.

The Champ was a CT, Land Rover wasn’t.

Humber 1-Ton Truck

The Truck, Armoured, 1 Ton, 4×4 (or Humber Pig) was based on the FV1600 series trucks produced by Rootes Group and designed by FVRDE.

Manufacturing started in 1952, following the first prototype in 1950.

... the Humber had a complex and well-styled body compared to other military vehicles.

Although expensive, the Humber did perform well, it was a CT vehicle.

3,700 Humbers were produced.

Bedford RL

The Bedford RL was a 3 Ton vehicle that was taken into service because of a dawning realisation (with experience from Korea) that the Ministry’s grand plans for CT (CombaT) vehicles were unrealistic.

Bedford produced a prototype vehicle precisely 3 weeks after an enquiry letter from FVRDE asking about the general possibility of supplying 6,000 trucks!

The RL was a 4-wheel drive version of the Bedford S Type, unlike the CT types, it did not have a B Series engine.

Over 73,000 were eventually produced and it remained in service for three decades.

Like Land Rover, the RL was not a CT vehicle.

AEC Militant

The 10-ton AEC Militant Mk2 and Mk3 were developments of a WWII vehicle called the AEC Matador.

Development of the ‘Knocker’ started in 1951 with production stretching into the early sixties. It was a commercially derived alternative (GS) to the Leyland Martian (CT)

A number of different variants were produced, including cargo, artillery tractors, cranes and recovery vehicles

The Militant was much more successful than the Martian, again, CT versus GS.

The derived hypothesis is that for vehicles required in small numbers, like frontline armoured vehicles, bespoke specs and standardization is justified. On the other hand, if you figure you are going to need thousands then you are better buying off open production lines such as those supplying the civilian market.

Get the one that is cheap and good enough.

Diminishing Returns – The British Army and its Vehicles – The Fifties - Think Defence

The end of WWII was followed by a period of reflection for the British Army, but not a long one.

www.thinkdefence.co.uk

www.thinkdefence.co.uk

FJAG

Army.ca Legend

- Reaction score

- 11,311

- Points

- 1,160

Nostalgia again. At the time I had Grade 9 autoshop and was the driver for my reserve unit's 3/4 command post. We were able to do all kinds preventative and minor maintenance on our vehicles. The only time they really went into the shop was when someone wrappped them around a tree.And I love to make this argument - keep it simple, stupid. No fancy electronics (they can break at the worst times). I learned to drive a Dodge 3/4 ton just before they were retired. They were shit simple.

- Reaction score

- 5,322

- Points

- 1,140

People these days don't learn to fix, and keep mechanical engines running. You'd end up just as stranded by a breakdown, but you'd have a less efficient vehicle while it was running.And I love to make this argument - keep it simple, stupid. No fancy electronics (they can break at the worst times). I learned to drive a Dodge 3/4 ton just before they were retired. They were shit simple.

For most electronics issues you'd just need a override that lets the vehicle run with a fault, until it can get sorted by the Veh Techs after the mission. Even in WWII, they tended to replace parts in the field, and ship them to the rear for repair.

Similar threads

- Replies

- 13

- Views

- 13K